CNC machining technology processes target products directly with high accuracy with three-dimensional data programming and division. The CNC process involves computer-aided design (CAD) and computer-aided manufacturing (CAM) programs, which are written in proprietary code called G-Code and M-Code. Machined parts can be powder coated, anodized, phosphatized, or finished with other surface treatments. The surface can be assembled immediately after treatment, effectively reflecting the design characteristics of the product.

CNC machining materials

| Plastics | Metals |

|---|---|

| Metamid | Steels |

| Danamit | Aluminum |

| PP | Zinc |

| POM | Brass |

| PE | Copper |

| PA | Bronze |

| EPS |

Machines can be found in our company

CNC machining centers

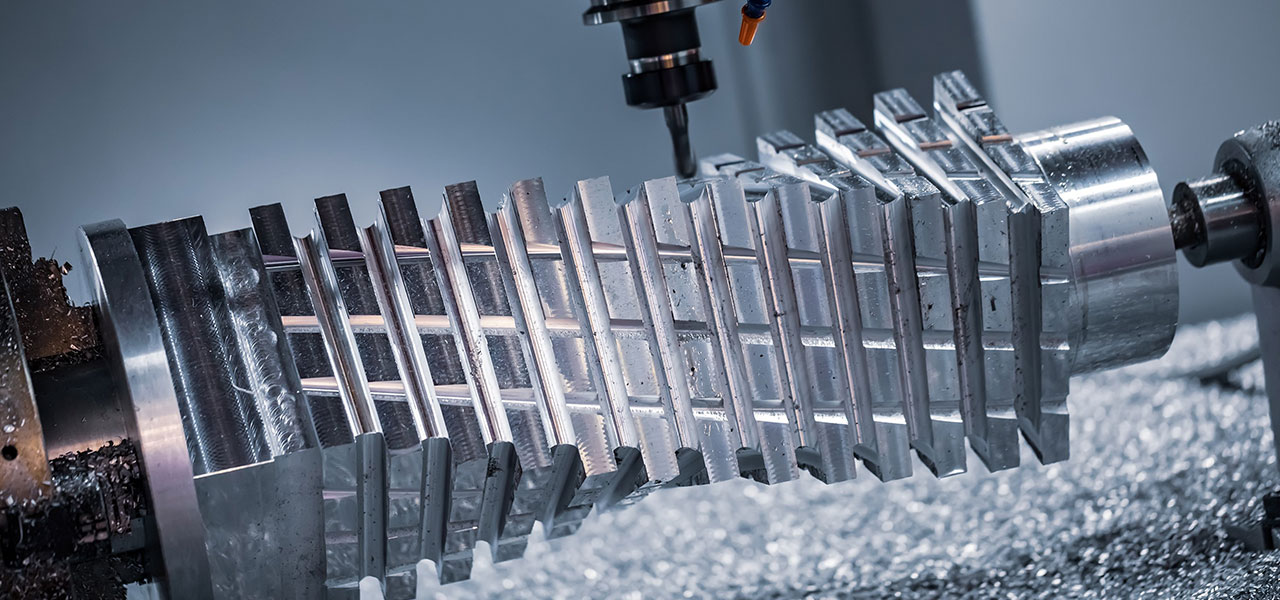

The CNC machining center is able to run programs consisting of alphanumeric instructions that guide the tool through different distances on the & nbsp; workpiece. Thanks to the computer control, better shape fidelity is achieved. & nbsp; The basic milling machines are made in three-axis design (X, Y and Z), we are able to meet the needs of our customers up to 4 axes.

Machining range

1020x500x500 mm 500 kg (3 axis)

600x180x180 120 kg (4 axis)

CNC lathes

On lathes, the workpieces are machined in a circular direction with & nbsp; tools. With CNC technology, the cutting used by lathes is done precisely and at high speed. CNC lathes are used to produce complex constructions that would not be possible with conventional hand-operated versions. Overall, the control functions of CNC-powered milling machines and lathes are similar. However, most CNC lathes consist of two axes X and Z axes.

Machining range

Ø65x1000 1000 kg